Prodcuts

Contact

Tel: +86-519-88381518

Tel: +86-519-88389757

Mobile: +86 18068528818

E-mail: cw@cwmotor.cn

Add: Hugang Bridge, Economic Development Zone,Changzhou, Jiangsu,China

CW230 stepper motor driver

1、 Introduction

1. Descriptions

The CW230 driver is a cost-effective and high performance stepping driver. The design is based on an advanced control technology. It applies to two-phase or four-phase hybrid stepping motor below 3A,such as 57BYG,42BYG. Due to the adoption of the advanced bipolar constant-current chopper driver technology. It shows many features such as stable operation and excellent high speed torque. It has 7 kinds of micro-step, and the maximum number of micro-step is 1/64. Chopping frequency of 20000 times per second can eliminate the noise of the motor. Another unique function is that it can automatically reduce current: when the motor is stopped, the output current reduces to a lower value, thereby reducing the heating of the motor and driver.

Supply voltage range from 18VDC to 40VDC ,the output current can be set from 0.9A to 3A; with automatic idle-current reduction, self-test, over-voltage, under-voltage and over-current protection.

2. Features

• high performance, low price

• micro-step

• Automatic idle-current reduction

• Optical isolating signal I/O

•Max response frequency up to 70Kpps

• Low temperature rise, smooth motion

• Online adaptive PID technology

3.Applications

It is suitable for a variety of small-scale automation equipments and instruments, such as labeling machine, cutting machine, packaging machine, plotter, engraving machine, CNC machine tools and so on. It always performs well when applied for equipment which requires for low-vibration, low-noise, high-precision and high-velocity.

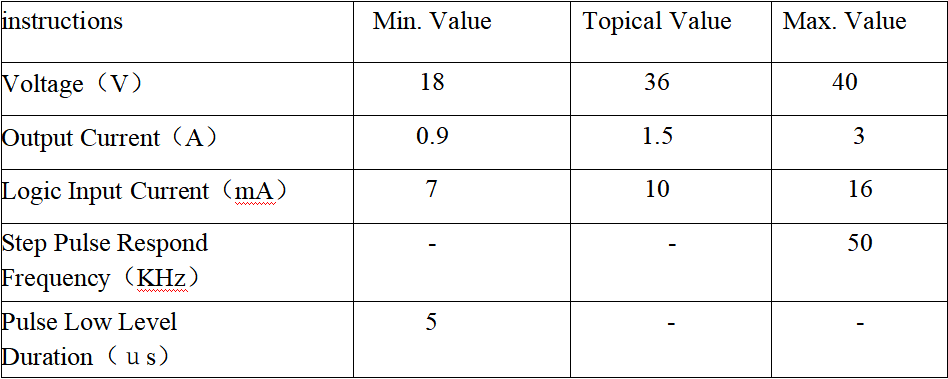

4. Electrical parameters

二、 Parameter setting

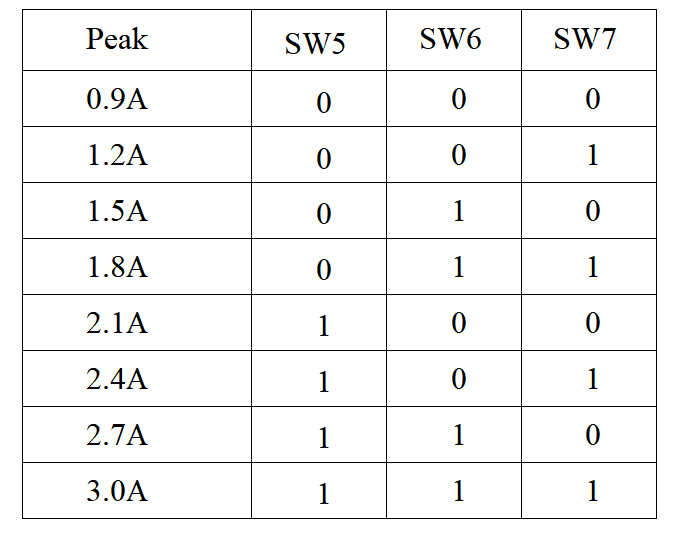

1. Current setting

Dial switch: on=0; OFF=1

2. Standstill Current Setting

If the host controller does not send the signal in half a second step, the drive will automatically enter power-saving semi-liquid state, phase current of motor winding will be reduced to half of the set, in this state, motor and drive power can be reduced, but the motor output torque is also reduced accordingly. Recovery automatically the output current rating when next pulse arrives.

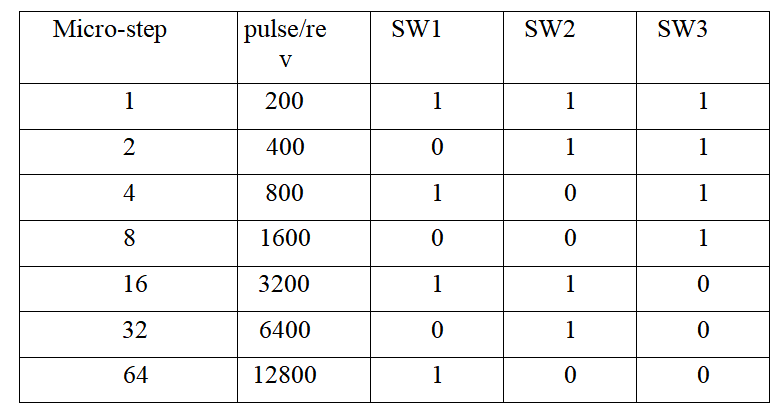

3 Micro-step setting

Dial switch: on=0; OFF=1

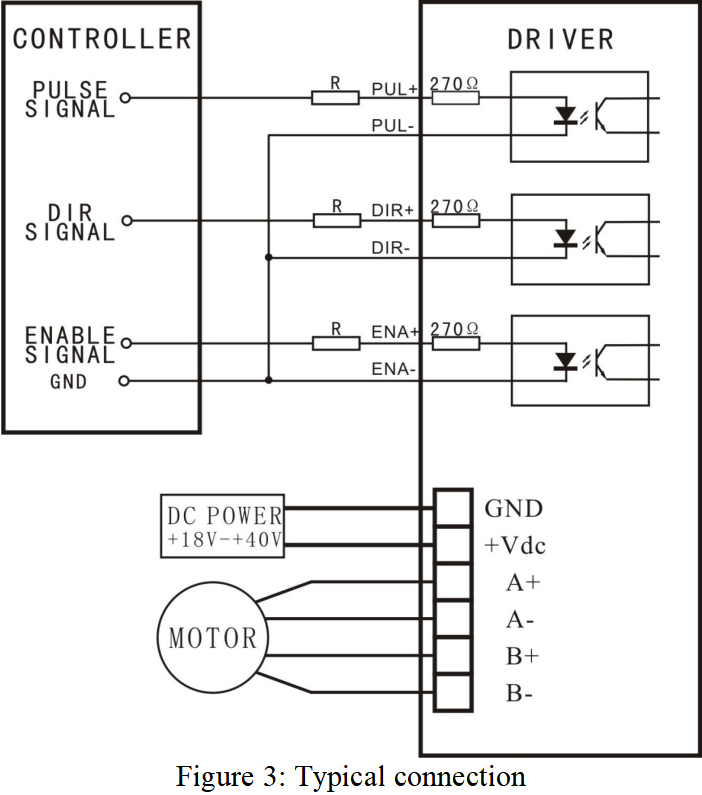

三、Connectors and Pin Assignment

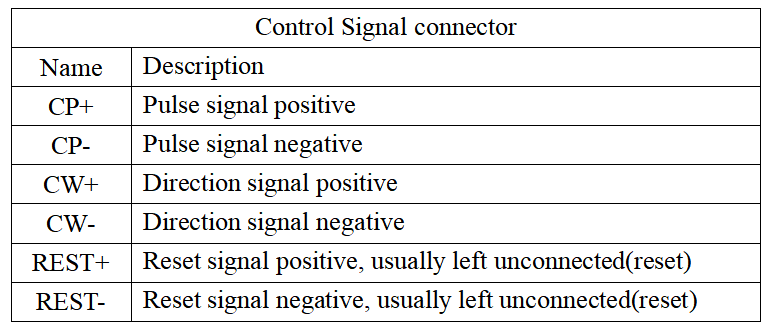

1. Control signal Connector

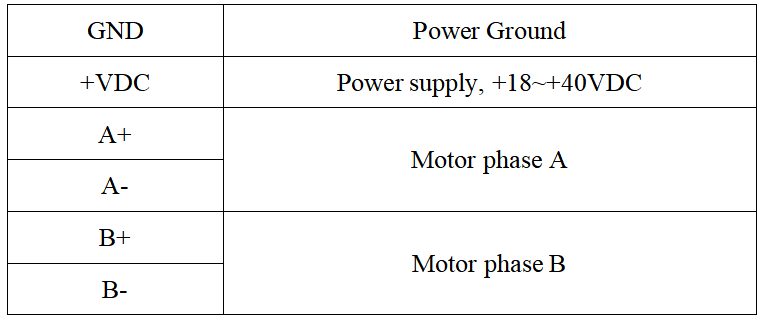

2. Power and Motor Connector

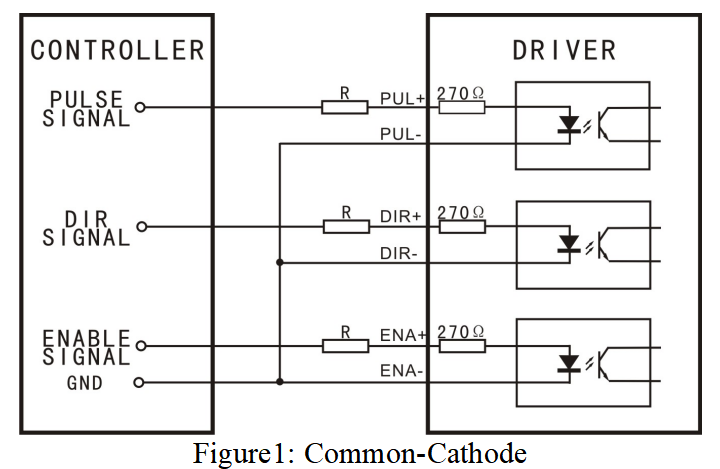

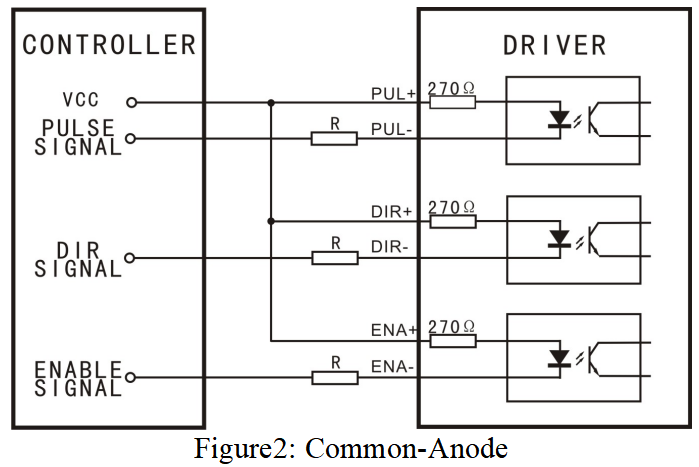

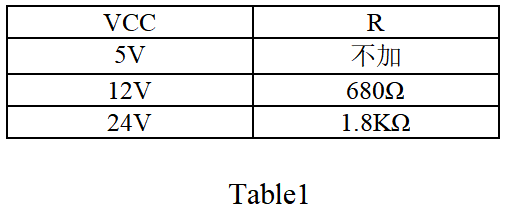

3. Control Signal Connector Interface

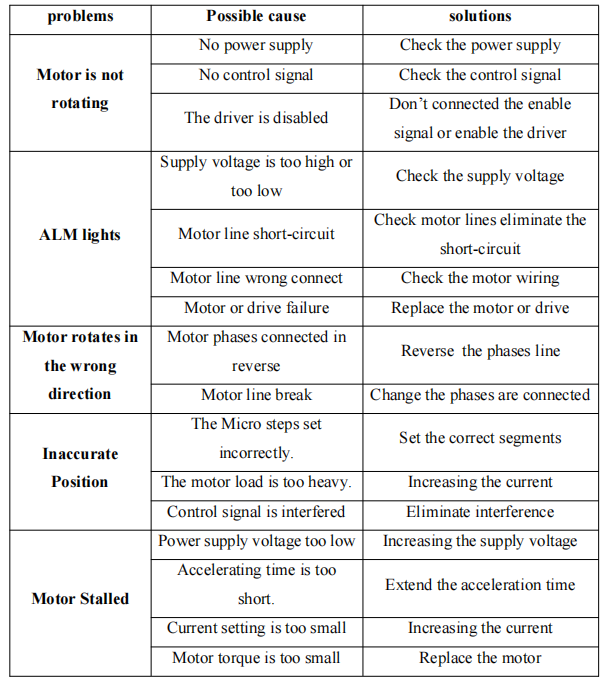

四、Problems and Solutions

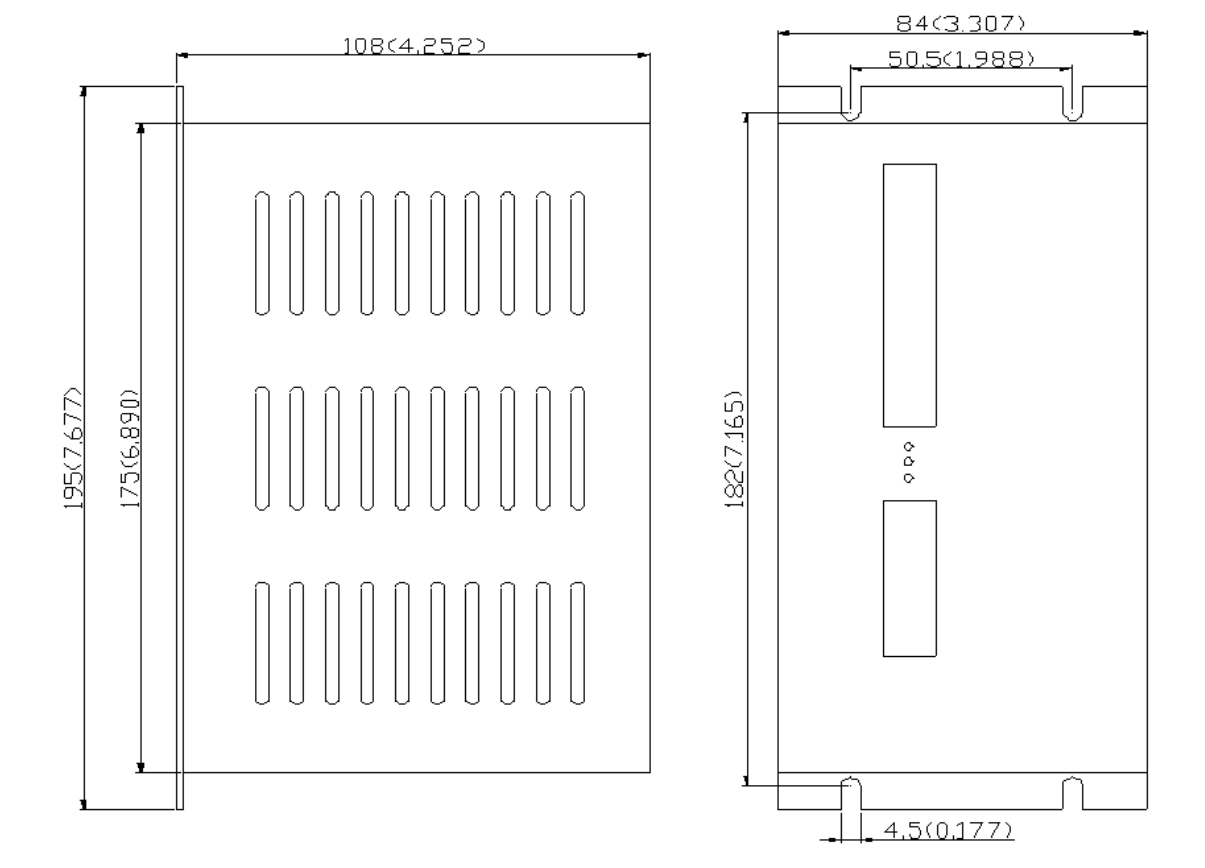

五、Mechanical Specifications (unit: mm(inch),1 inch = 25.4mm)

Related Products

Feedback

Contact

Mobile:+86 18068528818 (Elaine Yang)

Add:Hugang Bridge, Economic Development Zone,Changzhou, Jiangsu,China

Follow Us

Changzhou Chuangwei Motor & Electric Apparatus Co., Ltd Powered by: www.300.cn Changzhou 苏ICP备2021012447号-1